[Before I get started, allow me to just vent for a moment. I spent all of Sunday trying to get my 1979 Jeep Cherokee Golden Eagle’s replacement AMC V8 engine running. Should I have been editing, writing, answering emails, researching, and hiring? Yes. But instead I was elbow deep inside what has to be the most poorly designed engine I’ve ever had the misfortune of dealing with. The shittiness of the AMC V8 is severely jeopardizing The Autopian’s future outlook; that’s fitting, in some ways. Anyway, it’s not solely my frustration that’s leading me to write this article; the AMC 360 truly is a poorly-designed motor, as I will now show]. You may know American Motors Corporation as builder of the greatest Jeep engine of all time, the AMC inline-six, a motor that came primarily in 232 cubic-inc, 258 cubic-inch, and 4.0-liter displacements. This long iron-block motor, found in pretty much every Jeep between 1970 and 2000 — was absolutely unstoppable (If you want to be “in” with the Jeep crowd, just say “That foar leeter is bulletproof I tellya” anywhere near a gas station) thanks to its simple design, ease of serviceability, and plentiful low-RPM torque. It’s surprising, then, that the same company that built that amazing off-road motor developed the AMC V8, a contraption whose only reliability was liability, and that was ubiquitous in AMC products for decades. The thing went in damn near everything as the “step-up” from the six cylinder, even though, really, it was a huge step down. Let’s take a look at some machines burdened with hauling around this iron menace. Probably the best-known example is the Jeep Grand Wagoneer, which got the AMC V8 as an option over the inline-six:

The AMC Gremlin also offered the V8 if you didn’t want the standard six:

AMC Javelin? Yup, AMC V8 option:

Jeep CJ-5? Sure, you could get this motor instead of the trusty 258:

Jeepster Commando? Yup, 258 standard, 304 optional:

AMG Pacer: Oh yeah, standard six, 360 optional:

That huge anchor weighed down the front-end of lots of AMC products, including — sadly — my 1979 Jeep Cherokee Golden Eagle, which I worked on this past weekend:

Sadly, some non-AMC products also got this awful motor, including Malcolm Bricklin’s Canadian creation, the SV-1:

I’m fairly sure fellow AMC-lovers are going to come out of the woodwork to defend the AMC V8, which came primarily in three variants: 304, 360, and 401. “Mine has driven over 200,000 miles,” some will say. “This guy just doesn’t know how to wrench,” others will claim. “It was a torque, stout motor,” many will cry. “Some of these have been built into highly successful race motors” others will assert. And to them I say: Wake up. I was a sheep like you once, having fallen head-over-heels for the American Motors way of life. The soulful designs; the charmingly weird blend of Ford, GM, and Chrysler parts; the generally-stout hardware; and just the bold, Smallest-Of-The-American-Automakers rough-and-tumble way of doing things. Like you, I used to see AMC vehicles, especially Jeeps, through rose colored glasses. Hell, I currently own seven AMC-era Jeeps, and I’ve owned many more in my past! I even visited Kenosha a few years ago solely to pay homage to AMC, and I recently snuck into the old American Center former headquarters in Southfield, Michigan. I’m a diehard AMC fan, believe me. But I have no choice but to call a boat-anchor a boat-anchor, because that’s exactly what the AMC V8 is. Yes, as much as it pains me to admit it, the engine powering the beloved Jeep Grand Wagoneer and my badass 1979 Jeep Cherokee Golden Eagle is one of the worst powertrains in Jeep history. Here’s why.

The Oil Pump Literally Eats Itself

Let’s start with what’s absolutely ruined my experience with my 1979 Jeep Cherokee Golden Eagle, a beautiful machine dripping with soul, and one that I should love, but — thanks to this motor — I actually deride. Of all the things a motor has to do to survive, right up at the top when listed in order of importance is “make sure metals don’t rub against each other.” The way engines typically make sure bearings don’t rub against journals and camshafts don’t wear against lifters is they put a little cushion of oil between moving metal parts. Oil is the lifeblood of any internal combustion engine, which is why the AMC 360’s lubrication problems are such a big deal.

I ran my engine last summer and heard a loud noise at the top end, making me think that perhaps there was some kind of oiling issue. I removed the valve covers and, sure enough: bone dry. There was no 10W-30 making it up top. Why was this? Well, the oil pump on the AMC 360 is driven by the distributor; this is fairly common among old engines. So, to see what was going on, I bought a priming tool, chucked it up in my high-torque handheld drill, and spun that pump at 500 RPM through the hole where my distributor once was. Thirty seconds in, I saw no oil flow to the top end. A minute in: Nothing. Two minutes in: A tumbleweed rolls across my rocker arms. Sonuva bitch. I removed my oil pump from the bottom of my motor and re-packed it with vaseline, as is the recommended procedure to ensure that it primes properly. With the oil filter off, I turned the pump and, sure enough, oil poured out of the oil filter adapter. And yet, with the filter back on, no matter how much I spun that pump, nothing got to the top end. Worse, I noticed very little resistance on that drill when I spun it clockwise (which I’m fairly sure is the right direction). So while there appears to be some amount of oil flow, there’s very little oil pressure — the fresh 10W-30 appears to be flowing freely…somewhere… instead of to the top of the motor. Something ain’t right.

The bearing clearances on this motor looked fine the last time I checked them, and there was no sludge in the pan. Plus, the oil pickup tube looked fine. And what’s weird is that I did an oil pressure test while the engine was idling and read over 40 PSI while cold using a mechanical gauge; that’s not amazing, but not horrible, either. So I’m confused why there’s no oil getting to the top of the engine, though at the same time, deep down, I know what the issue is.

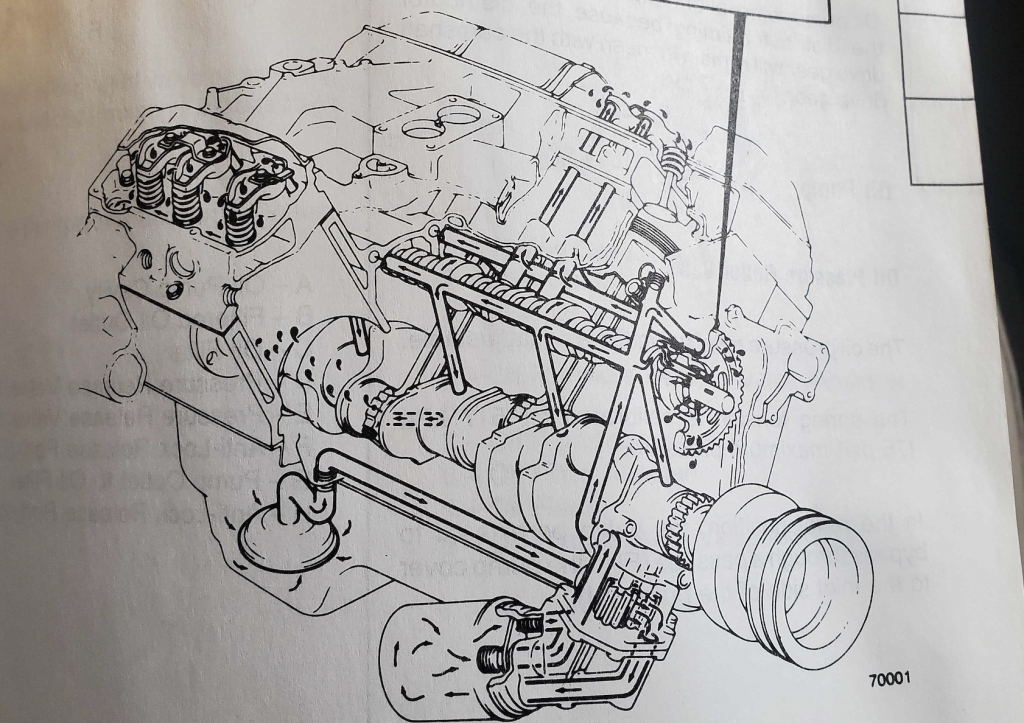

One of the most common failure points on an AMC 360 V8 is the oil pump itself. American Motors engineers found a clever way to integrate a number of items into the aluminum timing cover at the front of the engine. That cover not only fulfills its purpose of enclosing the timing chain, but it also houses the water pump, distributor, fuel pump, oil filter, and oil pump. I’d consider it clever integration if it hadn’t been so poorly executed.

As you can see in the image above, the oil pump consists of two steel gears riding in an aluminum housing. As is probably unsurprising to many, the result of this setup is that the gears wear into the aluminum housing, and over time, the distance between the oil pump gears and aluminum part of the pump increases, causing a severe reduction in oil pressure. What you end up with is my situation — pumping action is severely reduced, and while there may be oil pressure when cold, you can forget about it when hot. And lack of oil pressure when hot is a very, very bad thing — it will lead to failure of your rod and main bearings, camshaft lobes, rings and cylinders, and much more. Basically, the engine will destroy itself in short order. Lack of oil flow is a terrible thing, and the fact that the oil pump on the AMC 360 is basically a wear item is pathetic.

And to be clear, when I say the oil pump is a wear item, I’m referring to the entire timing chain cover. That whole aluminum piece that houses the distributor, fuel pump, oil pump, and oil filter adapter. The thing whose replacement requires one to remove the crankshaft pulley using a special puller tool. Of course, you also have to take out the radiator, fan, unbolt the whole accessory drive — it’s a nightmare (more on that job in a bit). And when you’re done, you get to drop $250 on a new timing chain cover, and even then, many forum-goers complain about performance even with the new pump and cover.

Even When The Pump Works, The Rear Cylinders Still Don’t Get Enough Oil

The sad thing is, even if the AMC V8’s timing chain cover and oil pump cover haven’t worn themselves out yet, the engine still may suffer from lubrication issues. That’s because the block’s internal oil passages are designed in such a way that, when the engine is run hard, the rearmost cylinders can be starved for oil. Here, let Great Lakes 4×4 member Leanz break it down for you: The bypass, shown above, is a fairly common modification, though it’s no easy job. It requires one to remove an absurdly heavy cast iron intake manifold, along with everything that mounts to it — and that’s a lot of stuff, especially on a smog-era vehicle like my 1979 Jeep Cherokee Golden Eagle. The bypass consists of an AN fitting inside the intake valley between the lifters for number 6 and 8. Drill and tap for the fitting in to the oil passage.

It’s Really Not That Easy To Work On

You might think that an old engine like the AMC 360 has a huge advantage over modern cars when it comes to serviceability, but I don’t know that that’s true. My 1979 Jeep Cherokee Golden Eagle was built right in the middle of the smog era, meaning it’s outfitted with more vacuum lines, air pumps, and other emissions-reduction equipment than you can even imagine. Add the fact that my Jeep is a high-end machine with power steering, air conditioning, and cruise control, and the rather enormous engine bay begins to shrink, yielding — as Chrysler’s packaging would often say when I worked there as an intern — “a basket of snakes” or, my favorite, “ten pounds of shit in a five pound bag.” Even simple things aren’t that easy to service. The rearmost spark plugs, especially the one on the passenger’s side by the heater core, are a pain in the arse to access:

And like I said earlier, replacing that timing chain cover is an awful job. One that I will likely have to do soon. (Dammit). The cover is wedged between the water pump and engine block, and damn near everything is bolted to it. To remove that cover will require dismantling the whole front of the engine.

And to dismantle the front of the engine means removing the giant harmonic balancer on the crankshaft — a job that requires a special tool and, critically, space. To get that space, I’d have to remove the fan on the water pump and take out the radiator. It’s all just a huge pain in the butt.

It Makes No Power And Sucks Gas Like You Wouldn’t Believe

Here’s the thing. Many, many great engines have achilles heels. The unstoppable Buick 3800 V6 has intake manifold problems. The beloved Cummins 12-valve has the Killer Dowel Pin issue. AMC’s own inline-six — one of the greatest engines of all time — tends to crack cylinder heads if it overheats even once. But those engines generally don’t require as much work to fix their maladies, and their fixes tend to yield a lifetime of reliable service. What’s more, none of those engines are as inefficient as the AMC V8. The 1991 Jeep Grand Wagoneer — the last vehicle to use the AMC 360 in the U.S. market– was a 4,400 pound behemoth whose AMV V8 made 144 horsepower. 144. That’s less horsepower than this 2011 Hyundai Elantra:

That Hyundai, by the way, scores 32 MPG combined. And while you might expect it to offer better fuel economy given its relatively diminutive size, newer powertrain and transmission technology, slipperier body, etc., I bet you wouldn’t expect it to offer nearly three times the Grand Wagoneer’s combined fuel economy of 11. Three times. Okay that’s still not fair due to the size difference, but let’s compare the new Grand Wagoneer, which literally weighs one ton more than its predecessor. It makes over three times as much horsepower at 471 HP and scores roughly 33% better fuel economy (15 MPG versus 11).

Obviously, comparing modern cars to old ones is silly, but that’s not the point. The point is that the poorly-designed AMC 360 has singlehandedly ruined my relationship with my beautiful 1979 Jeep Cherokee Golden Eagle. I should be cruising down Woodward in style, listening to that three-speed General Motors TH350 shift through those three gears, enjoying the gentle rumble of that V8, and looking over that distinctive hood. I should be living the dream, but because of the AMC 360, I’ve been dealing with the Amber Heard of automobiles — something so beautiful, and yet so troubled. And NO, that 327 was NOT a SBC. It was a boat anchor from the early 50s, but once rebuilt I’d smoke assorted pony cars in that weird old Ambi with a 3spd + OD manual “twin stick”. And yeah, I know, this is an old article. Deal with it. Is it possible to shim those oil pump gears with a simple Stainless Steel shim plate between them and the cover or between them and the pump cover to get the tolerances right again? The oiling mod to the rear is not needed, nor advisable. If your engine has been built properly, the oiling system is perfectly fine for stock to hi performance builds. Old, ignorant urban legends refuse to die and the people who spread them do not know how ignorant they are. Those of us, who do things correctly, do not hasve these problems. As for the 360 being a piece of garbage, that is a big load of garbage. My 360 kicks ass. It has properly designed components in it, not cheap garbage. Yes. The AMC oil pump (specifically the timing gear cover) is the short fuse in that particular engine because it tends to start wearing to the point it affects oil pressure after (OMG!) 150,000 to a quarter million miles with responsible maintenance, while the rest of the engine is showing less wear than a smallblock chevy at half the mileage. Suck it up, buttercup, and fix/maintain the problem if you want to keep the vehicle that long… just like everyone does with every engine ever made and whatever its particular “short fuse” issue may be. And with a little more conservative oil changes and a little more expensive engine oil it just may never rear its head at all. Just because it’s not the quirk you are familiar with and can conveniently ignore in your favorite engine, doesn’t make the engine inferior in any way, shape or form. I dismissed AMC engines for decades, and was decidedly “Mopar or no car.” That was my bad… and I’ve learned the good points after owning one for a while and actually getting to understand the issues and their solutions rather than gloss over them dismissively. https://fsjnetwork.com/forum/viewtopic.php?t=9536 You could be making that Jeep run better than new, while learning something new. I wouldn’t exactly throw a Chrysler B-block outta bed for eatin’ crackers, but I think Matadors and the big Ambassadors with the police package usually carried the 401, which as others have pointed out was the same block but with stronger innards. They were very popular and might even have been the fastest police sedan for a year or two, admittedly when that was a low bar; Los Angeles, both city and county, used them a lot. The 360 wouldn’t be my choice for an engine to really hammer on, but mine did okay considering the above.

- I once pulled a factory original plug out of a 1980 V6 Cutlass with 80k on the clock; removing and replacing it took about half an hour and one click at a time from various combinations of every socket extension and flex joint I owned. Why, yes, it’s the rearmost one on the passenger side, down under the heater/AC core. Not the only way that car reminded me that “aint” is at the heart of “maintenance”! First off, while the AMC six can run with a remarkable amount of wear, I’ve seen plenty that didn’t make it to 400k miles (or even 150k miles) as everyone who owns one thinks they can. Most common problem I see is rod bearings, and people drive them 50k miles after they start making noise so the crank is worn slam out. They have bad fuel economy, a ton of hoses and low power (until the 4.0) as well. Secondly, many of the complaints about the 360 are rightfully to any V8 of the era, not just AMC V8’s. Tons of hoses, bad access to many things in the engine bay, need of a harmonic balancer puller, low power etc. Now to some solutions: I had a 82 Cherokee Chief, and found a stock Motorcraft 4350 4bbl and manifold from a 70’s Waggy in junkyard. I threw them on my Chief and instant power upgrade was in effect. It ran so much better. I currently have a 76 Jeep CJ-7 with a 304. I needed the heads rebuild (it ran pretty good even with leaky valves on 3 cylinders) and while it was apart I threw in a cam (Crower Baja Beast) and a Edlebrock 4bbl intake and Edelbrock 600 cfm carb I had laying around along with a new timing chain. Instant massive power increase. Since you need to take the timing cover off – what a great time to do this upgrade. Note when you do this swap you can throw most of the vacuum hoses in the trash. The AMC log manifolds are pretty good, actually so you don’t need to splurge for headers (although I like the sound with dual exhausts.) The other option is an engine swap. To all the people saying 360/5.9L Dodge, why not a 360 Ford? I mean they all have 360 cubic inches, so they must be the same, right? The answer is no, they aren’t all the same, they all have different bellhousing patterns and mount locations; understandable given they are build by competing manufacturers. A Chevy small block is the easiest as the mounts and bellhousing adapters are readily available in the aftermarket. Just make it easy and pickup a junkyard 5.3 (or 6.0 if you want to splurge.) You can either get a 4bbl manifold for it, or wire in the FI system.